The Grand Complexity of Pure Vanilla Flavor

By Dr. Raz krizevski – Vanilla Vida’s CSO

Vanilla flavor doesn’t just happen. It is cultivated. As we learn more and more about the parameters that shape this beloved flavor, we are able to create a controlled environment that produces unprecedented natural potency and differentiation.

Vanilla is universally known as the world’s most beloved flavor. But vanilla flavor is very diverse, and its development is influenced by a wide variety of parameters. This article aims to discuss the immense complexity of a flavor often taken for granted.

An intro to vanilla flavor formation

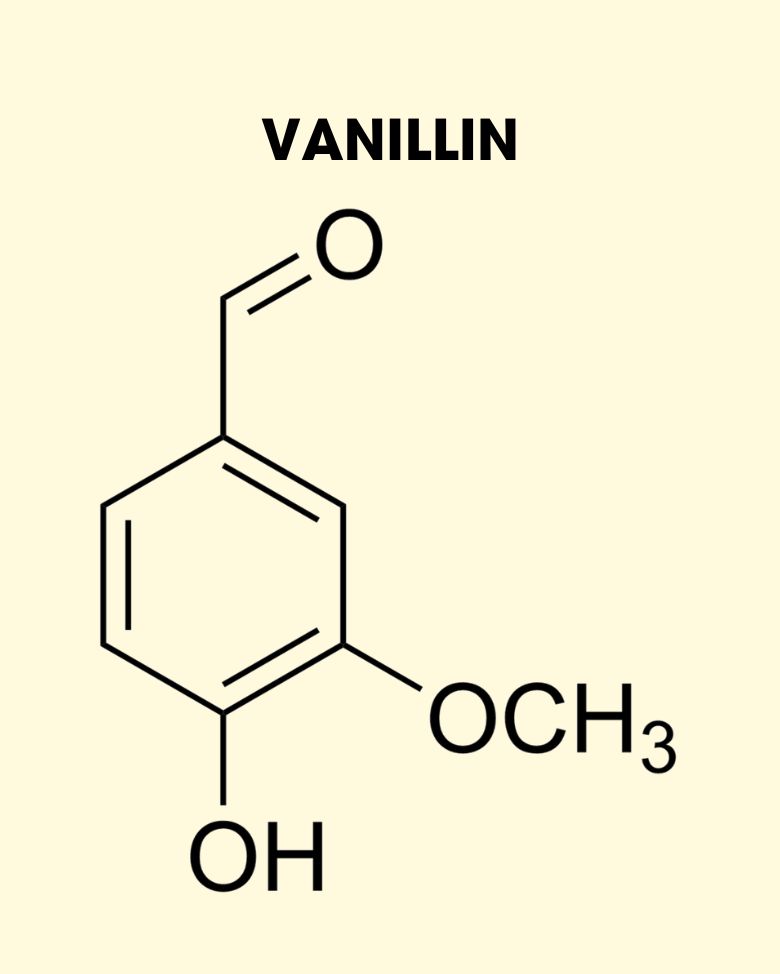

Green Vanilla beans mature on the vine for several months, accumulating flavor precursors. The most famous is glucovanillin – the direct precursor for vanillin, which is responsible for vanillic notes in vanilla flavor.

When green vanilla beans are harvested, they lack flavor and aroma. To convert precursors into flavors, the beans must undergo a process called curing. This is similar to flavorless green coffee beans that require roasting to develop the characteristic brew flavor we can’t start the day without. Vanilla flavor is determined by three key factors: harvest at the peak of chemical maturation, the efficiency in which precursors are converted into flavors, and the ability to prevent the evaporation of the newly formed flavors.

The vanillin level also serves as a quality indicator for other constituents. A high level confirms that the beans were picked when fully ripe and cured in a way that converts and maintains their full aroma. If we continue this line of thinking, beans picked at full maturation are predicted to obtain 5-7% glucovanillin (Van Dyk et al., 2014) but for different reasons and farm-level considerations, beans are picked earlier with approx. 2-4% (Pérez‑Silva et. al., 2021). Moreover, the average vanilla bean in the marketplace contains 1-2% vanillin, indicating the curing was performed in a way that either did not fully convert glucovanillin to vanillin, or resulted in the evaporation of vanillin and other flavor constituents.

Precise harvesting and full flavor potential fulfillment generate vanilla beans that are bustling with vanillin. A constant supply of these “super vanillin” beans ensures that users can manufacture high quality products over time. Therefore, it’s not surprising that precision agriculture have become our passion, here at Vanilla Vida. Needless to say, our agriculture is supported by innovative data processing and analysis.

Our potential fulfillment process

At Vanilla Vida, we grow vanilla at a state-of-the-art smart climate-controlled greenhouse. Our beans are picked after full maturation, and we verify that their glucovanillin content is indeed much higher than the market standards. We also work with traditional vanilla farmers who offer high-quality green beans. Their beans undergo analytical quality verification followed by curing in our novel data-driven indoor curing facility to ensure the full conversion of precursors to flavors and the minimal evaporation of produced flavors. We test our products at the end of the curing and conditioning to assess vanillin levels and overall flavor profile.

Our quality controlled process was developed to ensure that we reach optimal vanilla flavor potential fulfillment. During the process, each batch is analyzed at the green bean stage for its vanillin potential (both free vanillin and glucovanillin) as well as other key flavor precursors. A second analysis takes place at the packaging stage, during which fully cured beans are packaged and prepared for delivery. We then calculate our process efficiency, which helps us understand both precursor-to-flavor conversion efficiency and flavor loss (evaporation and catabolism). We are proud to say our indoor curing efficiency rate is above 90% for every batch.

Operating a fully controlled process allows us to monitor flavor development during curing (using GC-MS and sensorial analysis). This analysis is carried out every 2-3 days in several R&D batches. We then verify our findings in large-scale batches by testing several curing durations to define the best process conditions to generate a mature and rich aroma profile.

Let’s enable vanilla greatness

We give companies, businesses and culinary experts tons of credit for using natural vanilla instead of synthetic vanilla substitutes. But since natural vanilla differs in quality, we feel they deserve to work with truly groundbreaking products. By gaining insight into the flavor creation process and its variables, we hope that vanilla lovers will be able to reassess their expectations – and settle for nothing less than vanilla greatness.